The Industrial CoPilot project involved a Proof-of-Concept (POC) project for a global leader on the Heavy Engineering Industrial segment in India.

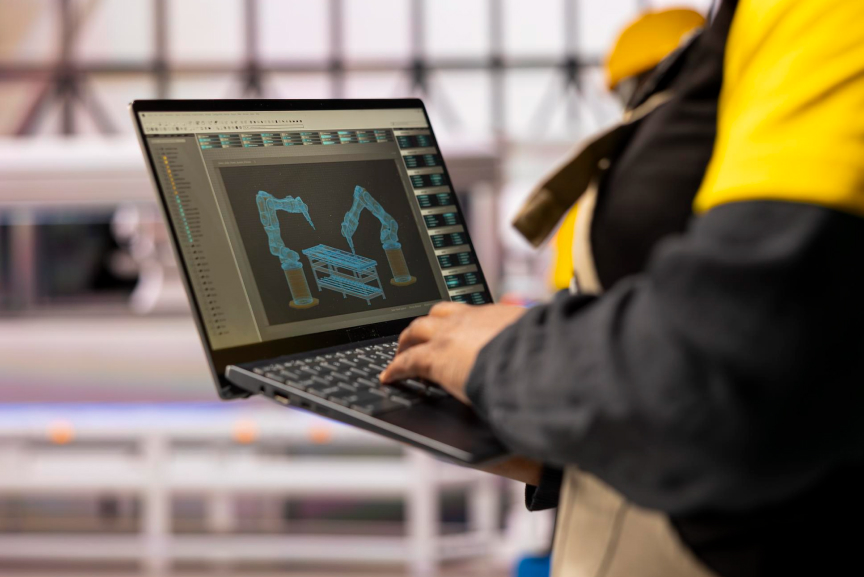

The project involved Industrial System Orchestration to reduce un-planned downtimes, reduce defect ratios, lower asembly-line anomalies and reduce EHS compliance issues and maintenance risks. The system involved diverse corporate management KPIs, OT, iOT devices iPCAM, Sensors, HVAC, Power and Water utility network, Viceo Cam inputs, assembline anomaly data, secure orchestrations for CoPilot integration on all digital devices. The CoPilot use Digital Twin based scenario analysis and provide decision supports for operators and management.

Customer Segment

The POC project is performed for the Heavy Engineering Industrial segment in India. The Heavy Engineering client had highly digitzed production systems with 3D modelling to injection moulding for metalic components for infrastructure construction sector.

Problem Statement

The Heavy Manufacturing client is a pioneering endeavor in India for Infrastructure sector. The initiative includes conceiving, designing, developing advanced AI/ML/DL and GenAI based CoPilot Assisted Manufacturing ecosystem with features for Predictive, Preventive or Assisted or Human-in-the-Loop (HIL) based Manufacturing and Supply-Chain Systems.

The project includes interactive CoPilot systems include features such as operators, managers, crew members. The goal of this engagement is to serve as a development partner to Microsoft and Client to build a scalable backend architecture from the ground up as Industrial CoPilot System. The system requries development and integrations and delivered as Future-Ready System to the Client by IBU Consulting as Service Provider.

IBU Approach

The Cloud Transformation is a long-term infrastructure Capacity Improvement and enablement process. The IBU Approach towards cloud transformation use a Technology Roadmap, Business growth and Evolution based Continuous Improvements on System KPIs and outcomes.

01

Improve Quality

Organic and Data-driven Product Quality Improvements using Digital Twins and CoPilot Asstants across Heavy Engineering Production Process. The product quality can significally by with timely information with CoPilot with AI/ML inference pipelines.

02

Reduce Defect Ratios

Agile CoPilot frameworks to provide a robust data-driven pipelines to support computerized CNC production machine operations and maintenance. The final products and operational quality KPIs are key for better ROI and market reputation.

03

EHS Compliance

The Industrial Shop Floors are prone to Environment, Health & Safety (EHS) related accidents and incidents resulting in asset and human health issues and loss. The CoPilot Systems for EHS factors involves many preventive AI/ML and GenAI features.

04

Reduce Cycle-Times

Reduction of Operational and Supply-Chain related Cycle-Time reduction using CoPilot and AI/ML based processes. The data-driven management and business governance would faster and better outcomes.

05

Reduce Waste Streams

Manufacturing processes have residual waste materials, anciliary ouputs external to finished products. The real-time data and analytics of the production line based intelligence with CoPilot features for waste reduction and support recycling and circularly.

06

Predictive Maintenance

Process mapping and systemic physics based preventive maintenance AI/ML models. The real-time analytics and CoPilot functions for Preventive Maintenance inference alerts and scenario data inputs.

Cloud Transformation KPIs:

- Hardware upgrades with Industry standards Lift & Shift procedures

- Acheive SLA based reliable Uptimes and Service Supports through-out transformation and post phases and post phases

- Reliable Private and Public Cloud Transformation with Data and HArdware Security.

- Low System anomalies and incompatibility post and during implementation stages

- BAU/SLA basedEscalation and Resolution of Cloud Infrastructure.

- Efficient Cloud Modernization and Transformation with Certified Engineers

- Monitor and Support Spend management of Cloud based infrastructure effectively

- Optimization for Continuous Improvements with SLA KPI terms and Compliances

- Responsive Capacity management to support User Volumetrics and Performance demand

- User friendly and elastic infrastructure Peformance and features

- Long-term Roadmap based Cloud infrastrcucture planning and execution

Leadership Vision

To identify and provide mid to long term Infrastructure Capacity Evolution pathways for RELIABILE, EFFECTIVE and RESPONSIVE compute environment using Cloud Server Transformations.

Outcomes & Results

Project Outcomes

- Create Cloud Transformation Journey and Roadmaps for long-term outcomes.

- Agile processes to continuously align system and feature for Client.

- Professionally Managed and transparant System Upgrades and performance Benchmarking (Pre & post).

- Compatible System Architecture Designs to align corporate functions and workflows.

- Lift & Shift Process that narrow the Performance and Functional KPIs.

- Provisions to migrate DevOps and support Cloud based CI/CD integrations.

- On-Premise A/D, Cloud and Hybrid Access Control & Security envelopes for Cloud migration.

- Quality process for Release & Deployment management after cloud transformations.

- Continuous BCP based Cloud Support and BAU Management.